Process equipment

Equipment that has been constructed by SIRRA typically includes strippers and scrubbers, droplet separators, small clarifiers, and various reactors. Apparatus is constructed tailor-made to the requirements of customers and the intended purpose of the item in question. The principal materials are weldable polymers, but also stainless and acid resistant steels are used. The advantage of using polymers is, beyond their moderate cost, their excellent chemical resistance. Equipment is constructed from pilot plant scale up to small industrial scale. Shown below are some examples of equipment that has been constructed by SIRRA.

Pilot plants

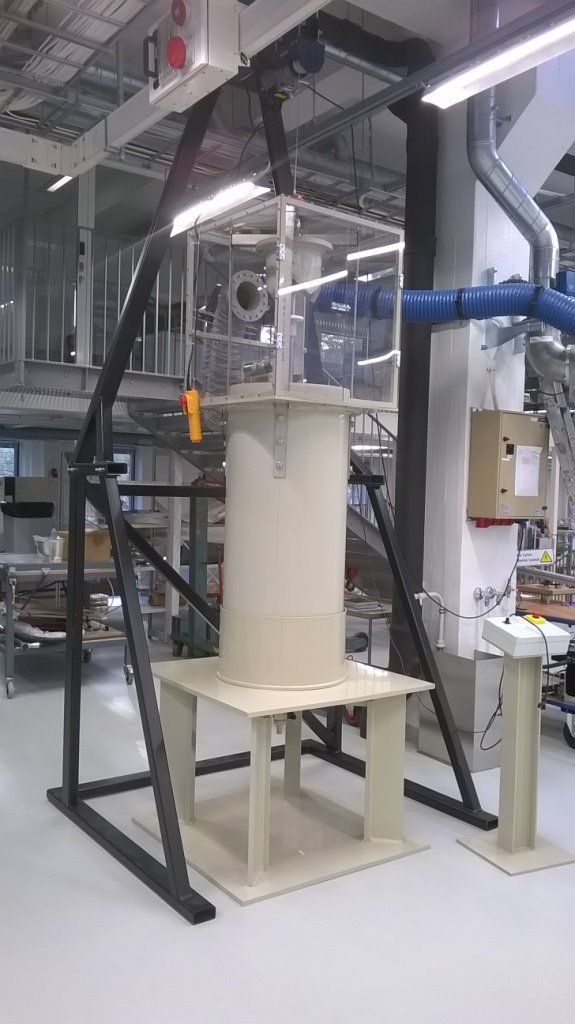

With pilot plants a process idea can be brought closer to industrial application than is possible with laboratory glassware. SIRRA’s apparatus is constructed very close to the way in which its full scale process plant equivalents are constructed, thereby showing, for example, the dynamics and capacity of the process, crystal sizes and habits, encrustation, and other features that are not revealed with glassware. When it comes to clarifying studies, transparent equipment can be constructed which allows a visual observation to be made of the progress of sedimentation where this would not otherwise be possible in industrial plants, and it also allows samples to be taken at various depths. Shown below are plants for stripping and absorption, which are applied in research into the removal of ammonia from biofuels.

Environmental protection

SIRRA’s process equipment can also be used in environmental protection work, such as cleaning gas streams or the clarification of moderately-sized waste water streams. Exhaust points, such as ventilation tubes in acid or ammonia tanks, gases from small scale processes, or equipment cleaning and sterilisation, or even sewer gas or laboratory emissions, occasionally give the plant operator a bit of a headache. Hazardous waste water may be generated, the stream not being large enough to motivate the procurement of large-scale sewage treatment plants. In many cases SIRRA can supply equipment with a reasonable relation between cost and the size of the stream that needs to be cleaned. The chemically durable and low cost polymer materials, in combination with SIRRA’s production technique, make this possible. Contact us, and we can discuss in confidence the chemistry involved and the appropriate apparatus that may be required.

Education

Equipment is also supplied for educational purposes. Shown below is a multi-functional bioreactor and a heat exchanger system (tube and plate).

Materials

The equipment is constructed mainly from weldable polymers such as polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), and other materials. In certain cases polyvinylidene difluoride (PVDF) can be used, or non-weldable Teflon. These polymers show excellent levels of chemical resistance, and their temperature range extends from -40oC to +140oC. With Teflon, even higher temperatures can be reached, but the use of this material is limited by its non-weldability. If transparency is required, thereby allowing as visual follow-up in a reactor, then transparent PVC, polyacrylate, or polycarbonate can be used. Occasionally glass is used in combination with the polymers.

Steel

We also construct equipment of acid resistant and stainless steel. The main rule is the right material to the right place. In elevated pressure and high temperature as well as i mechanical stress steel is often the only possible material. Typical uses are columns, agitators, support and suspension bars and machinery. For pilot scale plants TIG is the most widely used welding mehtod.

Examples of equipment constructed by SIRRA

References

| Year | Customer | Equipment | Substance | Use |

|---|---|---|---|---|

| 2023 | Afly | Scrubber | HCL | Environmental protection |

| 2023 | Välinge Innovation Ab | Scrubber | Titanium dioxide | Environmental protection |

| 2023 | Atria/Suomen Teollisuuskylmä | Scrubber | Ammonia | Safety |

| 2022 | Viking Malt/Adven | Scrubber and tank | Ammonia | Safety |

| 2022 | Fiskarsin kiertotalous Oy | Scrubber | Ammonia | Environmental protection |

| 2022 | Fiskarsin kiertotalous Oy | Storage tank | Ammonium sulphate | Production |

| 2021 | Sooma Oy | Reactor | Gel | Production |

| 2021 | Nordtreat Oy | Reactor | Wood impregnation | Production |

| 2021 | Fazer Lappeenranta/Suomen Teollisuuskylmä | Scrubber | Ammonia | Safety |

| 2021 | Fazer Lahti/Suomen Teollisuuskylmä | Scrubber | Ammonia | Safety |

| 2020 | Fazer Vantaa /Suomen Teollisuuskylmä | Scrubber | Ammonia | Safety |

| 2020 | Fazer Vantaa /Suomen Teollisuuskylmä | Scrubber | Ammonia | Safety |

| 2019 | Inex/Adven | Scrubber and tank | Ammonia | Safety |

| 2019 | Inex/Adven | Scrubber | Ammonia | Safety |

| 2019 | Valmet | Scrubber | Gases | Research |

| 2019 | SciTech-Sevice Oy | Reactor | Ozone | Research |

| 2018 | Vantaan Energia | Filtration plant | Waste water | Environmental protection |

| 2018 | Pöyry Finland Oyj | Gas sampling tank | Gases | Analysis |

| 2017 | Sooma Oy | Reactor | Gel | Production |

| 2017 | HK Scan/Adven | Scrubber | Ammonia | Safety |

| 2015 | ABB | Piping and tank system, demo | Water | Exhibition |

| 2014 | Nextrom Oy | Scrubber | HF-offgases | Environmental protection |

| 2014 | Stadin Ammattiopisto | Bioreactor | Microbes | Education |

| 2014 | Stadin Ammattiopisto | Heat exchanger | Water | Education |

| 2014 | Ductor Oy | Stripping plant, pilot | Ammonia | Research |

| 2014 | Ductor Oy | Stripping plant, lab scale | Ammonia | Research |

| 2014 | MTT (Luke) | Stripping plant, pilot | Ammonia | Research |

| 2012 | Lulekraft Ab | Scrubber | Hydrochloric acid fumes | Environmental protection |

| 2010 | Metso (Valmet) | Stripping plant, pilot | H2S | Research |